Woodpeckers

Woodpeckers Extended Slab Flattening Mill Pro (SLBFPRO-XL)

- UPC:

- 810018201555

- MPN:

- SLBFPRO-XL

- Availability:

- Lead Times Currently Unavailable - USTF Will Contact When Ordered

Description

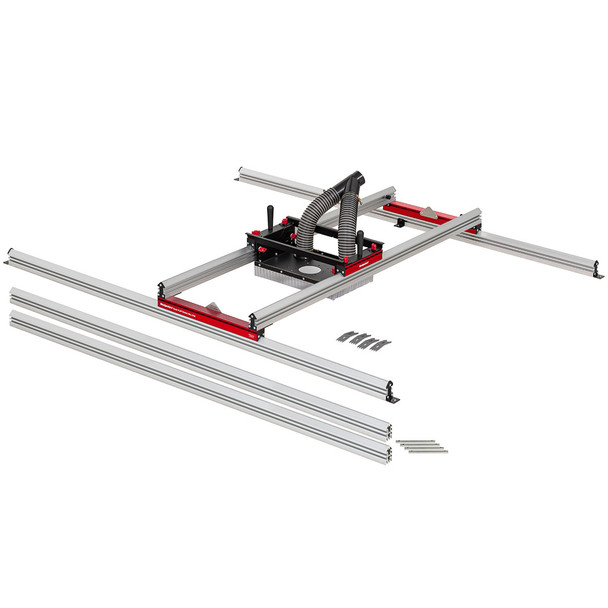

Woodpeckers Extended Slab Flattening Mill Pro (SLBFPRO-XL)

Imagine being able to mill a flat face on a live edge slab over 4-feet wide and up to 3-3/8" thick without having to shim the rails or your work piece. Or go the other way and imagine milling something just a fraction of an inch thick, again without shimming either your stock or the rails. Imagine milling slabs with virtually all the shavings being captured by your dust collector. It’s time to stop imagining and start milling with Woodpeckers NEW Slab Flattening Mill PRO. Working with feedback from thousands of Slab Flattening Mill customers we’ve redesigned the router carriage with a greater thickness range and integrated dust capture right at the source. The “PRO” details don’t stop with the feature-packed new carriage. We also extended the rails, increasing the standard width capacity to a massive 48-1/2" wide (using a 2” cutter…even more with a larger bit).

The hottest trend in interior design these days is live edge slabs. And, why not? The natural curves of the trunk give an organic feel. The crazy grain patterns in crotches and burls are eye-catching. Even cracks that would have sent lumber to the burn pile just a few years ago are being controlled and enhanced with butterfly patches and epoxy inlays. However, slabs present some challenges in the shop. Overall width and weird grain changes make the use of a jointer and thickness planer impractical if not impossible. But now you can accurately flatten live-edge slabs and other oversized stock faster and easier than you ever thought possible.

Woodpeckers Slab Flattening Mill PRO guides your router over your slab in a controlled plane. Since you’re using a router instead of a planer-style cutterhead, tear-out is minimal…and thanks to our uniquely engineered rails and enhanced solid steel carriage, the surface will only need light sanding afterwards. The router carriage is the main feature that sets the Slab Flattening Mill PRO apart from the earlier Slab Flattening Mill. The new carriage adjusts in height by a full 2-1/2". Depending on your router and router bit, you can work on stock just a fraction of an inch thick or up to 3-3/8” without ever shimming either the rails or the slab.

Using the Slab Flattening Mill-PRO is as easy as sliding your router across the slab and back, moving over and repeating until you’re done. This process produces lots of shavings. Judging by the number of customers who added the optional dust collection shroud to the original Slab Flattening Mill, dust collection is a highly sought-after feature. So, we decided to make it an integrated part of the new carriage. The twin pick-up points and rugged, full-surround curtain capture well over 90% of all shavings and dust.

Don’t beat yourself up if you bought the original and now love the features of the PRO…the Upgrade Kit puts the new router carriage on your existing rails. We also offer a range of surfacing router bits including ones with interchangeable carbide tips. For edge milling we offer down-cut solid carbide spiral bits in several diameters and cutting lengths.

Just like the original, you can get the Slab Flattening Mill PRO in either a Basic or Extended configuration. The Basic includes one pair of base rails which gives you a maximum slab length of 58". The Extended adds a second set of rails, extending the maximum slab length to 134" (that’s right…over eleven feet!)

Like all Woodpeckers products, the Slab Flattening Mill PRO is precisely machined and carefully inspected in our Strongsville, Ohio factory (just south of Cleveland). Don’t put off that natural edge project you’ve been dreaming about any longer. Order your Woodpeckers Slab Flattening Mill-PRO today!

- Country of manufacture: United States

FEATURES

- Flattening live-edge slabs for unique furniture pieces such as tables, benches, and bar tops.

- Milling wide slabs of wood that traditional jointers and planers cannot handle due to size constraints.

- Creating custom thickness pieces from oversized stock for specialized woodworking projects.

- Enhancing the natural features of wood, such as grain patterns, crotches, and burls, with minimal tear-out.

- Repairing and revitalizing wood with cracks by flattening surfaces for epoxy inlays or butterfly patches.

- Producing large, flat surfaces on wood slabs for use in interior design elements, adding an organic feel to spaces.

- Customizing the thickness of woodworking projects without the need for shimming, accommodating materials from fractions of an inch to over 3 inches thick.

- Integrating dust collection directly at the source for a cleaner work environment and reduced cleanup time.

- Expanding creative possibilities in woodworking by allowing for the accurate milling of unconventional and oversized pieces.

- Upgrading from previous models with an enhanced router carriage for improved performance and versatility in slab milling.